In the high-stakes world of Indian logistics, a trailer is far more than just a piece of equipment trailing behind a prime mover. It is the literal backbone of commerce, tasked with navigating punishing terrains, unpredictable weather, and the relentless pressure of delivery timelines. For those who have been in the trenches of the transport industry for the last few decades, one name consistently surfaces as the gold standard for reliability: SATRAC, a leading Trailer Manufacturer in India.

With a legacy spanning over 25 years, SATRAC has evolved from being a manufacturer to a strategic partner for India’s largest fleet owners. Their philosophy, “Forward As One,” reflects a deep-seated belief that the success of the prime mover, the trailer, and the customer are closely linked.

Twenty-Five Years of Hard-Earned Insights

The journey of SATRAC over the last quarter-century is essentially a history of the modernisation of Indian trucking. By working closely with operators on the ground, they have gained invaluable insights into how needs have shifted from simple hauling to complex, high-efficiency logistics. In that time, they have transitioned from a specialised truck body builder to a visionary designer of application-specific engineering that can survive the unique rigours of India.

Their primary insight is simple yet profound: a trailer must be an asset, not a liability. In an industry where margins are thin, the difference between profit and loss often comes down to the vehicle’s longevity. This is why their mantra, “Long-life Matlab SATRAC,” resonates so deeply with seasoned transporters.

Articulating What Really Matters

Many manufacturers talk about “quality,” but SATRAC articulates it through the lens of a fleet owner’s balance sheet. They understand that a partner cares about more than just the purchase price. They focus on a comprehensive checklist of value drivers:

- Payload Efficiency: Maximising every kilogram of carrying capacity without compromising structural integrity.

- Operating Uptime: Ensuring the vehicle stays on the road, not in the workshop.

- Resale Value: A SATRAC trailer typically retains 20% more value over time compared to other brands, making it a smarter long-term investment.

- Suitability for Indian Conditions: Engineering specifically for the heat, dust, and varied road quality found across the country.

Engineered for the Next Decade

SATRAC products aren’t just built; they are over-engineered for “no downtime, only uptime, for a lifetime”. This commitment is backed by serious technical specifications, cementing their reputation as the best truck body maker in India. They utilize BSK 46 and HSS 800 high-strength steel, which offers a yield strength of 450, which is nearly double the 250 yield strength found in many competitor products.

The heart of their trailers is a 500mm formed beam in a ladder-frame chassis, fabricated using fully automated SAW (Submerged Arc Welding). This ensures uniform weld quality and superior torsional stability. Furthermore, their use of precision jigs and fixtures ensures “zero-to-zero” alignment, which is critical for extending tyre life by up to 7% and improving overall fuel efficiency. To combat the elements, they employ Grit Blasting technology to prepare surfaces, ensuring superior paint bonding and corrosion resistance that protects the chassis for years.

A Multi-Industry Footprint

SATRAC’S versatility is evident in the sheer breadth of industries it serves. Their product line is categorised to meet specific sectoral demands:

- Mining: As a trusted tipper manufacturer in India, they provide heavy-duty rock body tippers and “U” shape box bodies to handle the most abrasive loads.

- Steel & Infrastructure: Providing flatbeds and low-bed trailers for transporting massive machinery and structural components.

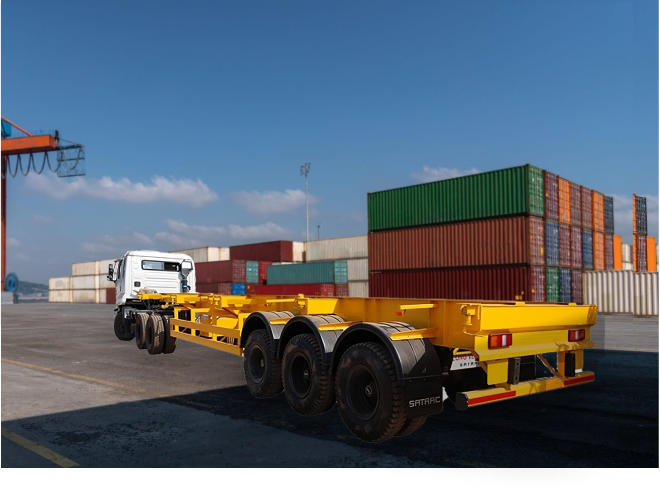

- Logistics & Shipping: Their skeletal trailers are staples in container transport and port operations.

- Cement & Power: Serving as a premier bulker manufacturer in India, they produce specialised rigid bulkers and bulker trailers to handle fly ash, alumina, and coal dust with precision.

Achievements and Industry “Firsts”

SATRAC’s impact on the industry is quantifiable and solidifies their standing as a top-tier commercial vehicle body builder in India. To date, they have delivered over 50,000 trailers and truck bodies, serving a base of more than 10,000 happy retail and corporate clients. Perhaps their most notable engineering achievement is the development of India’s first road-train trailer, a testament to their willingness to push the boundaries of regulatory and technical possibilities in the country. Additionally, they serve as a trusted partner to over seven major OEMs, who account for 50% of their production volume.

Trusted by the Best

The roster of SATRAC customers reads like a “Who’s Who” of Indian industry and logistics. Major names relying on their builds include:

- Logistics: CJ Darcl Logistics, Delhivery Limited, Union Roadways, and Transystem International.

- Steel & Mining: Tata Steel, JSW, SAIL, NMDC, and Adani.

- Cement: UltraTech, ACC, JK Cement, and Dalmia.

- Infrastructure: KNR Construction and DP World.

The Voice of the Fleet

Ultimately, the true measure of a manufacturer is the word of the people who rely on the equipment every day. The testimonials for SATRAC are telling. One fleet owner noted, “For 15 years, we haven’t even needed to call them for service!”. Another remarked on the lasting quality of the builds, stating, “The quality of SATRAC is evident. I am still running vehicles from 2008”.

For any transporter looking to move into the next decade with confidence, SATRAC represents more than just a trailer; it represents a 25-year legacy of engineering excellence that ensures you are never moving alone, but always “Forward As One”.